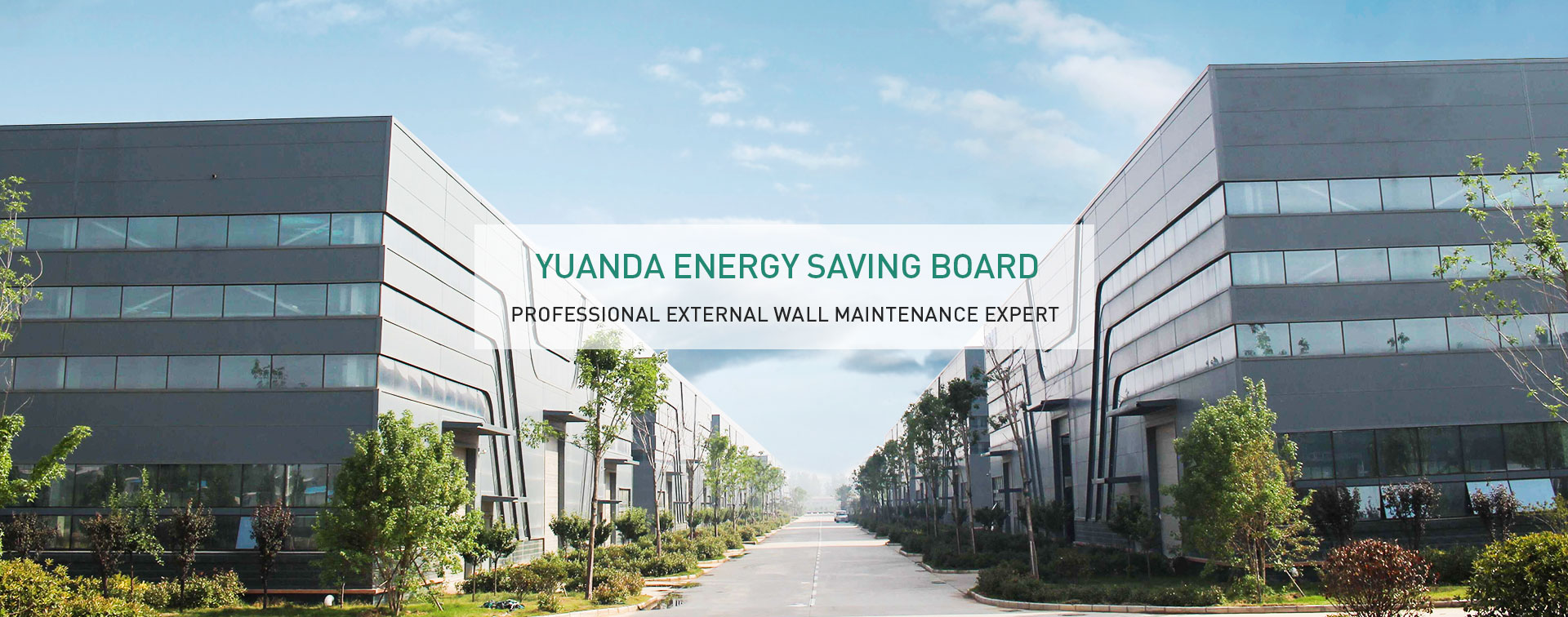

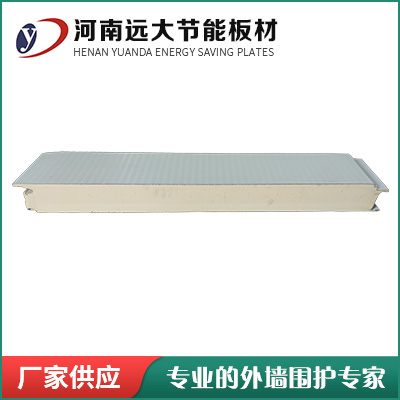

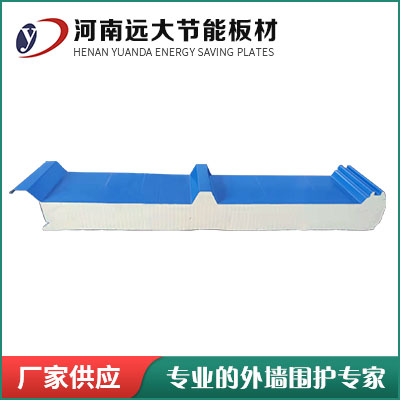

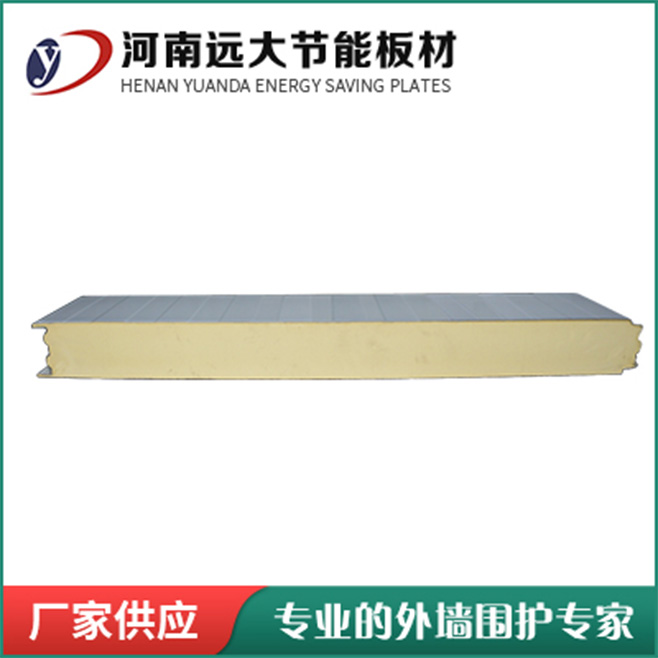

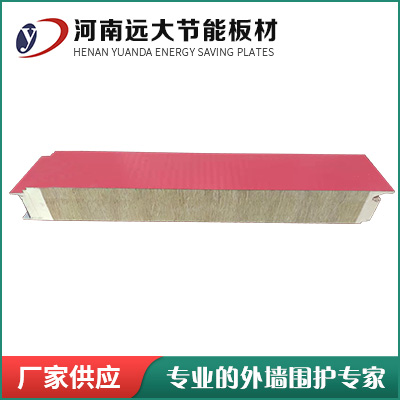

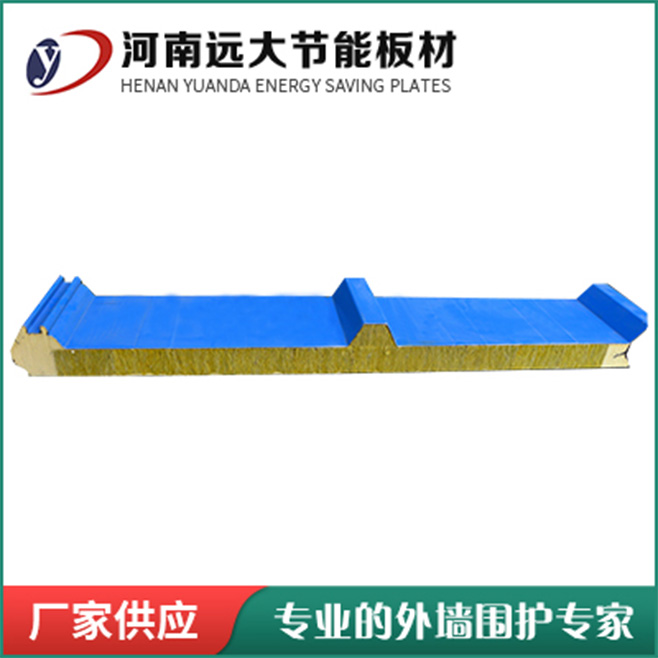

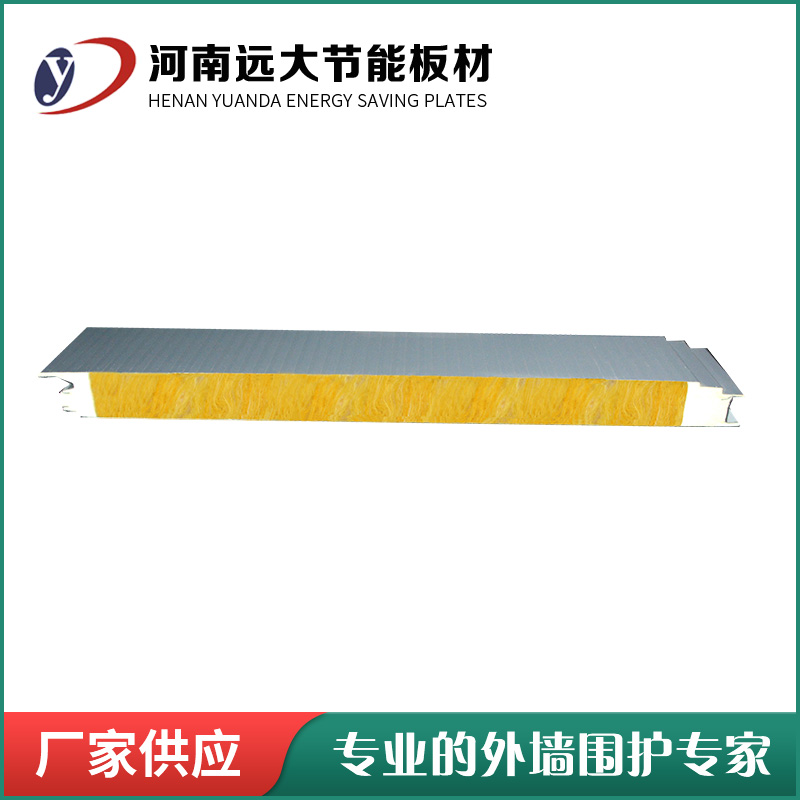

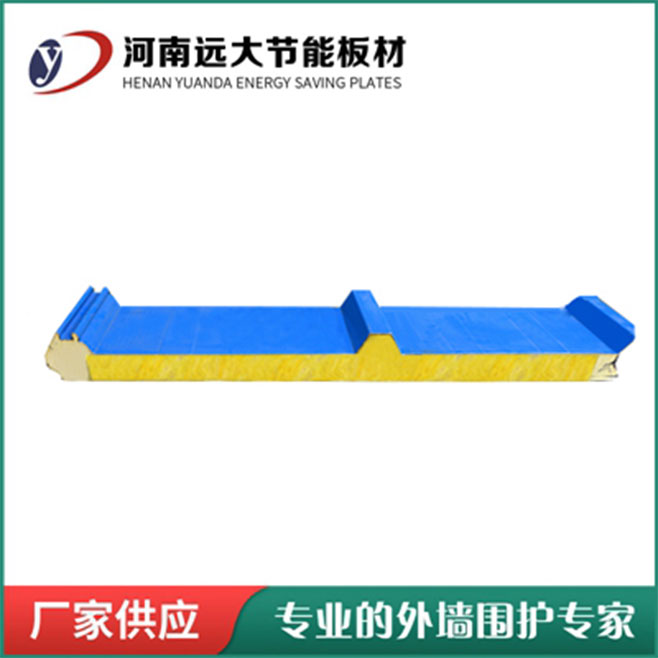

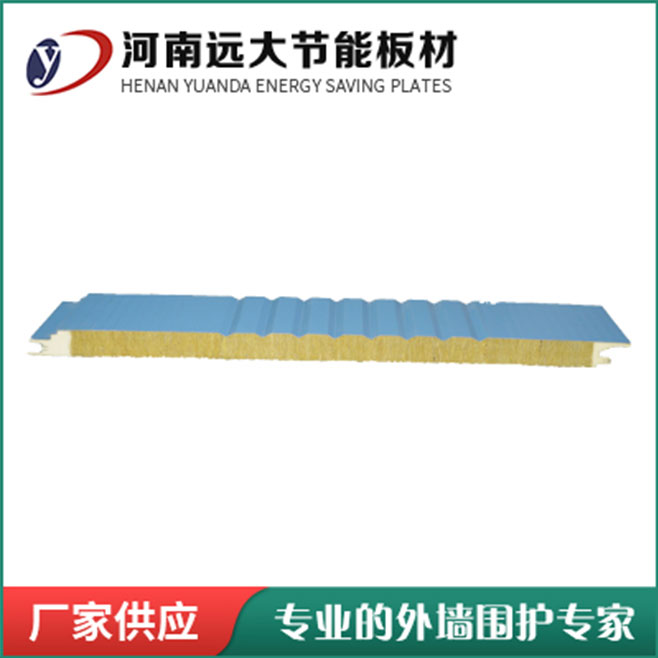

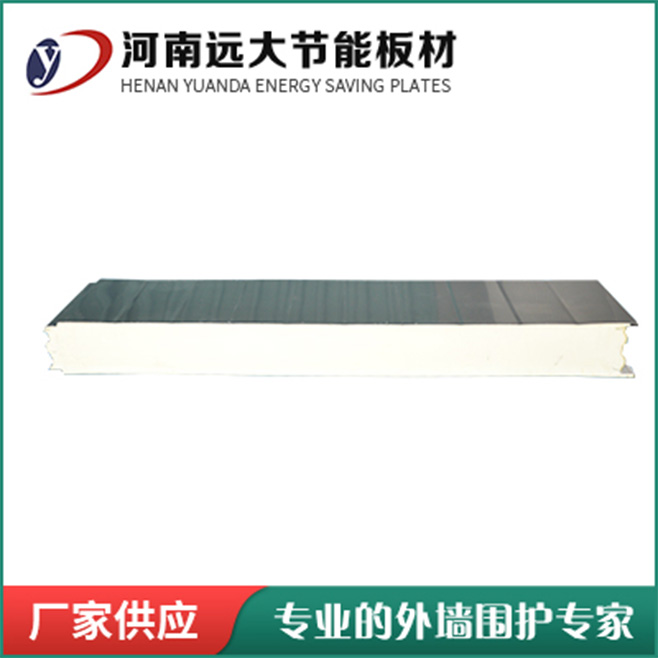

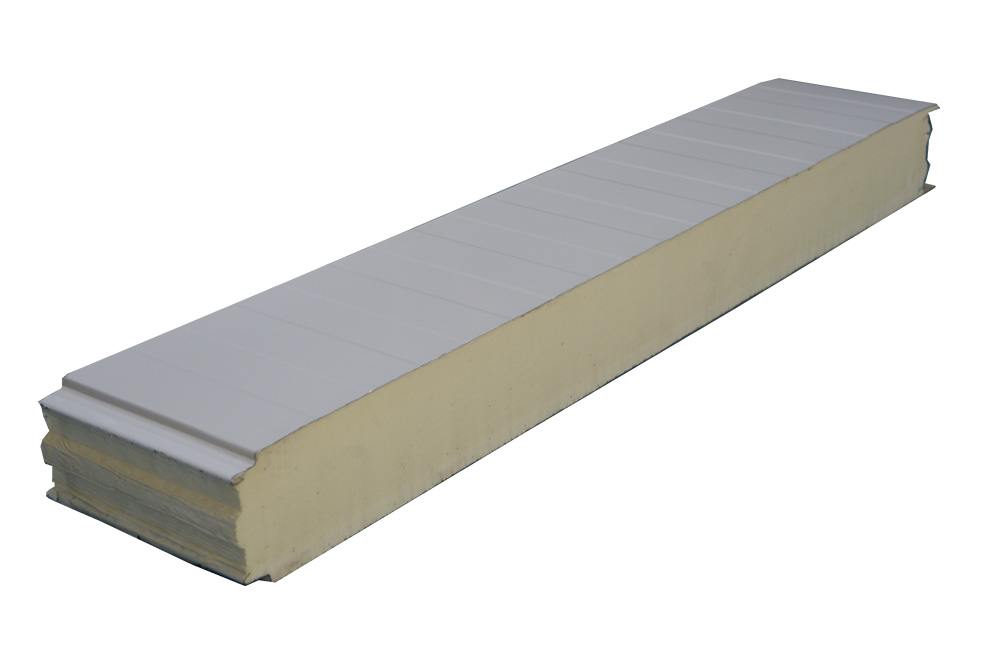

Polyurethane wallboard

Product features polyurethane wall panel is generally used for the roof outer panel of buildings, which has good thermal insulation, heat insulation and sound insulation effect, and polyurethane does not support combustion, in line with fire safety. The combination of upper and lower plates and polyurethane has high strength and high strength